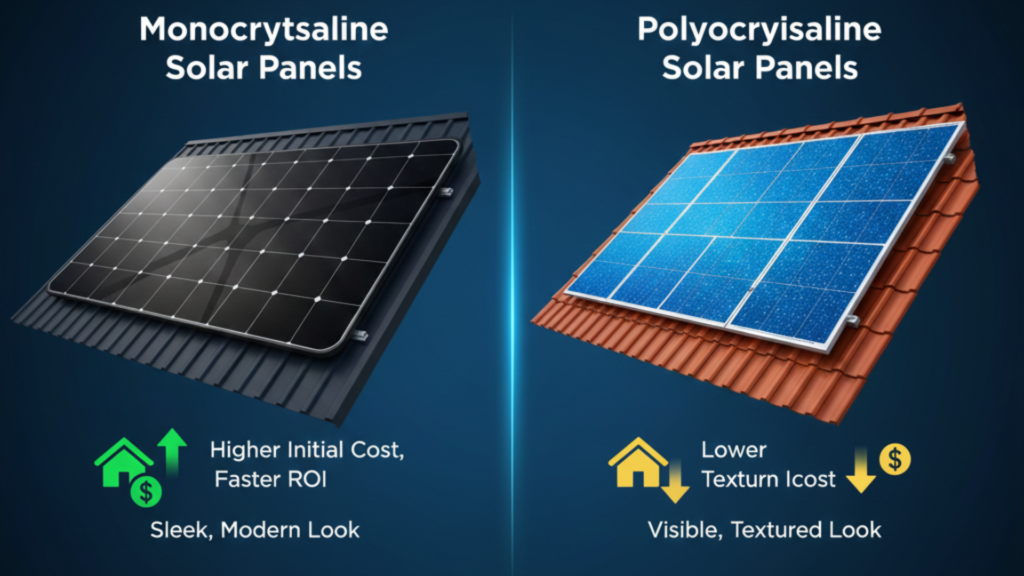

Choosing the right solar panel for your home or business is a critical step towards energy independence. The market primarily offers two mature technologies: Monocrystalline vs Polycrystalline solar panels. While both efficiently convert sunlight into electricity, their most immediate and noticeable difference is their color—the sleek black of monocrystalline and the distinct blue of polycrystalline.

This aesthetic variance isn’t an arbitrary design choice; it is a direct byproduct of the manufacturing process and the fundamental crystal structure of the silicon cells. Understanding this difference is key to making an informed decision about your solar investment.

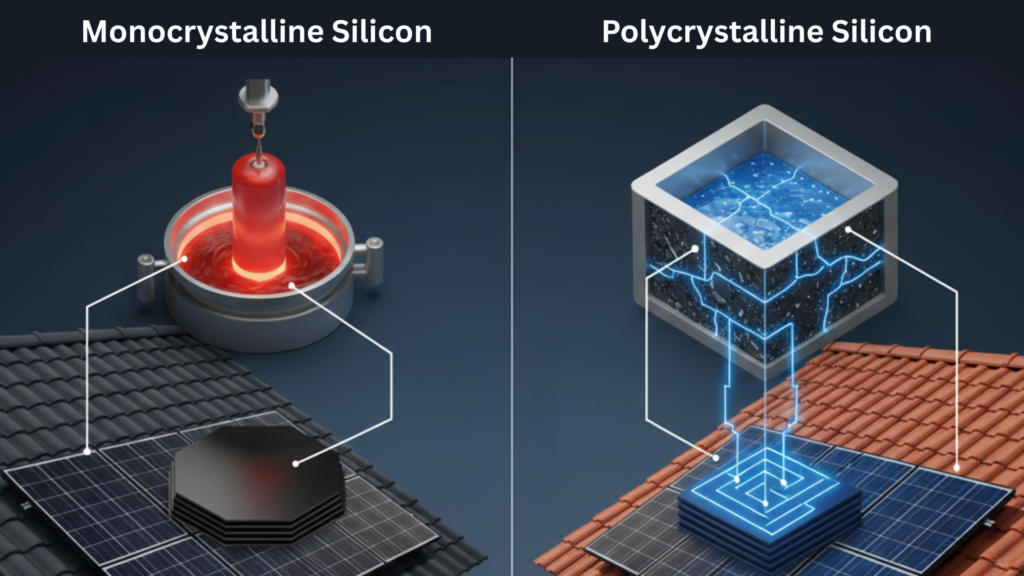

The Core Difference: Manufacturing and Silicon Purity

Both monocrystalline and polycrystalline panels rely on silicon, the second most abundant element in the Earth’s crust, as the semiconductor material to create photovoltaic (PV) cells. The path they take from raw silicon to a finished solar wafer, however, is dramatically different and is the root cause of the variation in color and performance.

Monocrystalline Solar Panels: The Black, Pure Powerhouse

The term “mono” means single. Monocrystalline panels are made from a single, highly pure silicon crystal.

The Czochralski Process: A High-Purity Birth

- Melting and Seeding: Manufacturers melt high-purity silicon in a crucible. They then dip a small, perfect seed crystal into the molten silicon.

- Crystal Pulling (Czochralski Process): Workers slowly and carefully withdraw the seed crystal while rotating it. As it cools, the molten silicon solidifies around the seed. This process forms a massive, single, flawless, cylindrical ingot of silicon crystal.

- Wafer Slicing: The ingot is then sliced into very thin, uniform wafers. These wafers typically have rounded edges or an octagonal shape to maximize material use from the cylindrical ingot.

Why They Are Black

The uniformity and high purity of the single silicon crystal are what give monocrystalline panels their characteristic smooth, deep black color.

- Light Absorption: The flawless, single-crystal structure allows light to interact with the silicon consistently. Manufacturers apply an Anti-Reflective (AR) coating to maximize light absorption. This coating, combined with the underlying pure silicon, results in almost all incident light being absorbed, not reflected.

- Minimal Reflection: Black is the color of maximum light absorption. With very little light being reflected, the cells appear a uniform, deep black.

Polycrystalline Solar Panels: The Blue, Budget-Friendly Option

The term “poly” means many or multiple. Polycrystalline panels, also known as multi-crystalline panels, are made from multiple fragments of silicon crystal melted and fused together.

The Casting Process: A Multi-Crystal Formation

- Melting and Casting: Workers melt raw silicon fragments and pour them directly into a square mold.

- Cooling and Solidification: The molten silicon is allowed to cool and solidify slowly. As it cools, the silicon forms a multi-crystalline structure, meaning there are many individual silicon crystals that grow haphazardly and meet at visible boundaries, known as grain boundaries.

- Wafer Slicing: The resulting silicon block is cut into uniform square wafers.

Why They Are Blue

The blue color is a result of two factors: the multi-crystal structure and the anti-reflective coating.

- Grain Boundaries and Scattering: The multiple silicon crystals within each cell have different orientations, creating visible grain boundaries where the crystals meet. These boundaries cause the light that isn’t absorbed immediately to scatter and reflect light differently.

- The Anti-Reflective Coating: A common anti-reflective coating applied to all silicon solar cells, typically composed of silicon nitride, is naturally a bluish color. On a monocrystalline cell, the underlying perfect black absorbs this coating’s color. However, on the polycrystalline cell, the grain boundaries and varied crystal structure cause more light in the blue spectrum to be scattered, making the overall panel appear a speckled, vibrant blue. The surface looks non-uniform, like shattered glass or a metallic granite, due to the visible crystals and grain boundaries.

Performance and Efficiency: Monocrystalline vs Polycrystalline Solar Panels

The structural differences that cause the color variations also directly impact the performance characteristics of the panels. This is the real core of the Monocrystalline vs Polycrystalline solar panels debate for buyers.

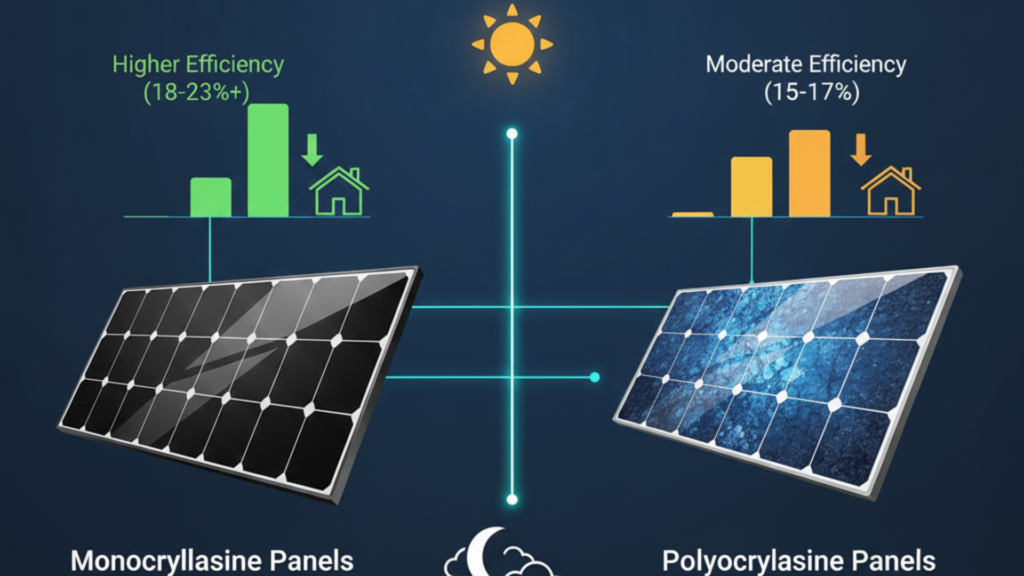

Efficiency and Power Output

| Feature | Monocrystalline Panels | Polycrystalline Panels |

| Silicon Structure | Single, pure crystal | Multiple, fragmented crystals |

| Electron Movement | Free and unobstructed path | Restricted by grain boundaries |

| Typical Efficiency | Higher (18% to 23%+) | Moderate (15% to 17%) |

| Space Requirement | Less space needed for the same output | More space needed for the same output |

The purity and single-crystal structure of monocrystalline silicon mean that electrons—which create the electric current—have a virtually unobstructed path to flow, resulting in higher efficiency and greater power output per square foot. This makes them the premium choice for limited roof space.

In polycrystalline cells, the numerous grain boundaries create imperfections that impede the flow of electrons. This internal resistance reduces the overall efficiency of the cell, meaning you need more panels (more space) to generate the same amount of power as a monocrystalline system.

Temperature and Low-Light Performance

The environment plays a significant role in solar panel output.

- Temperature Coefficient: Monocrystalline panels generally exhibit a lower temperature coefficient (e.g.,0.3% to -0.45% per °C). This means they lose less efficiency as the temperature rises above the standard test condition of 25°C. The high purity of the silicon helps them maintain performance in hotter climates.

Low-Light Conditions: Due to their superior purity and efficiency, monocrystalline panels generally perform better in low-light or cloudy conditions, and their power generation typically starts earlier in the morning and stops later in the evening compared to polycrystalline panels.

Cost and Aesthetics: Making Your Choice

Beyond performance, cost and appearance are often the final deciding factors for homeowners and installers.

Initial Cost and ROI

| Cost Factor | Monocrystalline Panels | Polycrystalline Panels |

| Manufacturing Complexity | High (Czochralski process is energy-intensive) | Low (Simpler casting process) |

| Material Waste | High (Silicon wasted from cutting cylindrical ingots) | Low (Silicon fragments are reused) |

| Initial Cost | Higher per panel/watt | Lower per panel/watt |

Polycrystalline panels are significantly cheaper to manufacture due to the simpler casting process and less silicon waste, making them the most budget-friendly option with a lower upfront cost.

Monocrystalline panels are more expensive initially, but their higher efficiency often means a faster return on investment (ROI) in the long run, especially in areas with high electricity prices or where power generation is a high priority.

Aesthetics and Installation

- Monocrystalline (Black): Homeowners often prefer the uniform black color because it tends to blend more seamlessly with dark-colored roofing materials. This provides a sleeker, more modern aesthetic. The octagonal or rounded cells also leave a visible, contrasting white or silver space between them on the panel’s backing.

- Polycrystalline (Blue): The speckled blue hue and the perfectly rectangular cells (with no gaps between corners) give these panels a more visible, less uniform look on a roof. While effective, the bright blue color is sometimes seen as less aesthetically pleasing than the sleek black of its counterpart.

Conclusion: Choosing the Right Solar Panel for You

The color of your solar panel—black or blue—tells the story of its creation, its crystalline structure, and ultimately, its performance. The battle of Monocrystalline vs Polycrystalline solar panels doesn’t have a single winner; the best choice depends entirely on your specific needs and priorities.

- Choose Monocrystalline (Black) if: You have limited roof space, you demand maximum efficiency and long-term energy generation, or you prefer a sleeker, uniform aesthetic.

- Choose Polycrystalline (Blue) if: Your main concern is the lowest possible upfront installation cost, you have ample roof space, and you accept a slightly lower efficiency rating.

In today’s rapidly evolving solar market, both types offer an excellent pathway to clean energy. By understanding the core difference in their construction, you can confidently select the panel that aligns perfectly with your budget, space constraints, and aesthetic preferences.

Frequently Asked Questions (FAQ) about Monocrystalline vs Polycrystalline Solar Panels

Q1: Is the color of a solar panel the only difference?

A: No, the color is merely a visual indicator of a much deeper difference: the internal crystal structure of the silicon cell. Monocrystalline (black) has a single, pure crystal, while Polycrystalline (blue) has multiple, fragmented crystals. This structural difference is the cause of the variation in efficiency, cost, and temperature performance.

Q2: Which type of solar panel is more durable?

A: Both technologies are extremely durable and typically come with a 25-year performance warranty. Historically, the high-purity monocrystalline cells were projected to degrade slightly slower and last longer, up to 40 years. However, technological advancements have significantly improved the durability and lifespan of both types, with most quality manufacturers offering similar warranty periods.

Q3: Which panel should I choose for a small roof?

A: If you have limited roof space but high energy needs, Monocrystalline panels are the better choice. Their higher efficiency rating means you will generate more power from a smaller number of panels, maximizing your limited area.

Q4: Which panel is better for a hot climate?

A: Monocrystalline panels generally perform better in hot climates. Their lower temperature coefficient means their efficiency decreases less significantly than polycrystalline panels when the temperature exceeds standard operating conditions.

Q5: Can I mix these two panel types in one system?

A: Avoid mixing panels in the same string (series of connected panels). The entire string’s output will be limited to the output of the least efficient panel (the polycrystalline type). If you must mix them, install them on separate strings connected to different inputs on your inverter. This allows each type to operate at its maximum potential.